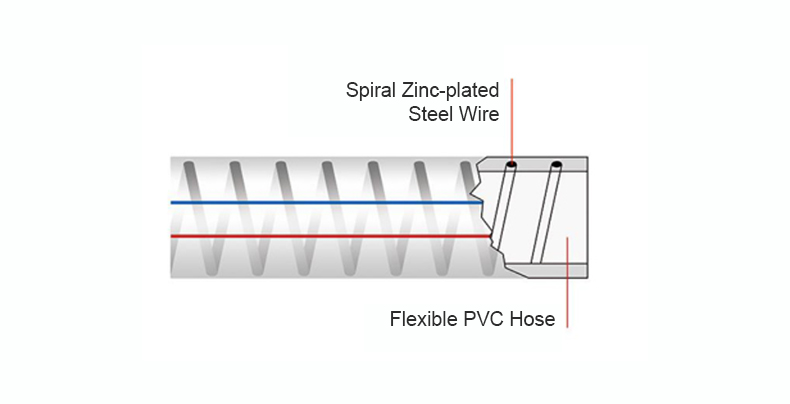

In terms of hose manufacturing technology, it is the Goldsione PVC steel wire hose extrusion line that leads. It makes hoses with a transparent wall composed of PVC thus contents within can easily be visually checked. The PVC material is also fortified by a spirally wound steel wire integrated within it, giving the hose a remarkable capability that withstands very high and low pressures. This steel increases the durability of the hose in even the harshest of conditions while at the same time preserving the lie of the hose.

The robust steel wire reinforcement helps the hose to withstand much higher pressures than normal. It holds its shape and effectively performs its functions even in very high-stress conditions. Being made of PVC plastic, these hoses operate well as they have an inbuilt ability to fight corrosion hence, they are durable and cut down on the costs of repair.

The configuration also allows for minimum static electricity accumulation which enhances the safety of the hoses in transporting flammable gases and liquids. With the aid of the steel wire reinforcement, the hoses can sustain a lot of internal pressures and hence are effective in use under high pressure. Standardization of hose manufacturing processes helps result in dependability in their performance during their use for machines, construction work, irrigation, and even vacuum.

At each stage of the Goldsione PVC steel wire hose extrusion line’s integrating efforts, High this and in particular raw material crafting of plants, ensuring accuracy and rapidity. Every phase from the first pipe extrusion up to the last inspection of product quality is completed in the strictest compliance with the industry’s requirements. This technological advantage will as well increase the efficiency of production processes but consistency in the production of superior quality products within strict requirements will also be assured.

For inquiries and further details, reach out to us: