In the realm of industrial production, efficiency and versatility are paramount. The PVC Suction Hose Machine Production Line stands as a testament to these principles, offering a comprehensive solution for the seamless creation of PVC suction hoses. With a design centered around quality and functionality, this production line serves as a cornerstone in various sectors, including agriculture, construction, and irrigation.

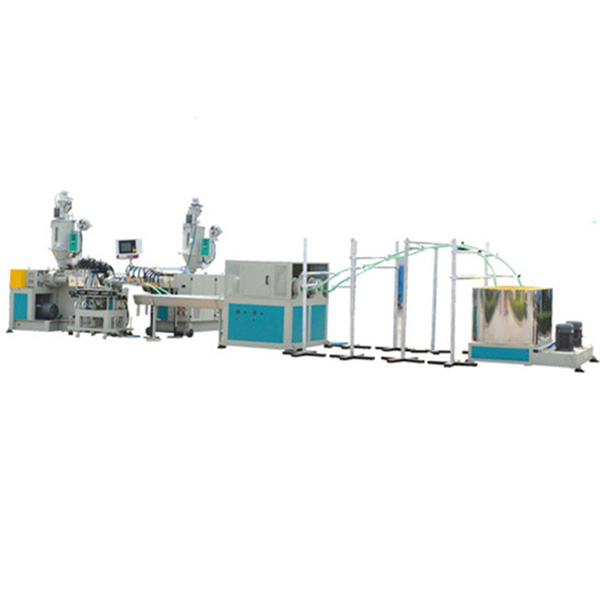

At the heart of this production line lie two extruders, meticulously engineered to ensure precision and consistency in the extrusion process. These extruders work in tandem, seamlessly blending soft PVC with a rigid PVC helix reinforcement. This fusion of materials results in a hose that boasts exceptional extrusion resistance, corrosion resistance, and the ability to withstand negative pressure—a trifecta of qualities crucial for demanding industrial applications.

As the extruded material takes shape, it passes through a specialized forming unit that imparts the hose with its distinctive dimensions and structure. This crucial step ensures uniformity and durability, essential for withstanding the rigors of real-world usage. Following formation, the hose undergoes a bath, where it receives additional treatment to enhance its properties further. This meticulous attention to detail guarantees that each PVC suction hose meets the highest standards of quality and reliability.

Upon completing its journey through the production line, the finished PVC suction hose is meticulously wound onto a winder, ready for distribution and deployment. The winder ensures neat and efficient packaging, facilitating easy transportation and storage—a testament to the holistic approach employed by the production line.

By seamlessly blending cutting-edge technology with meticulous craftsmanship, this the PVC Suction Hose Machine production line delivers PVC suction hoses of unparalleled quality and versatility.